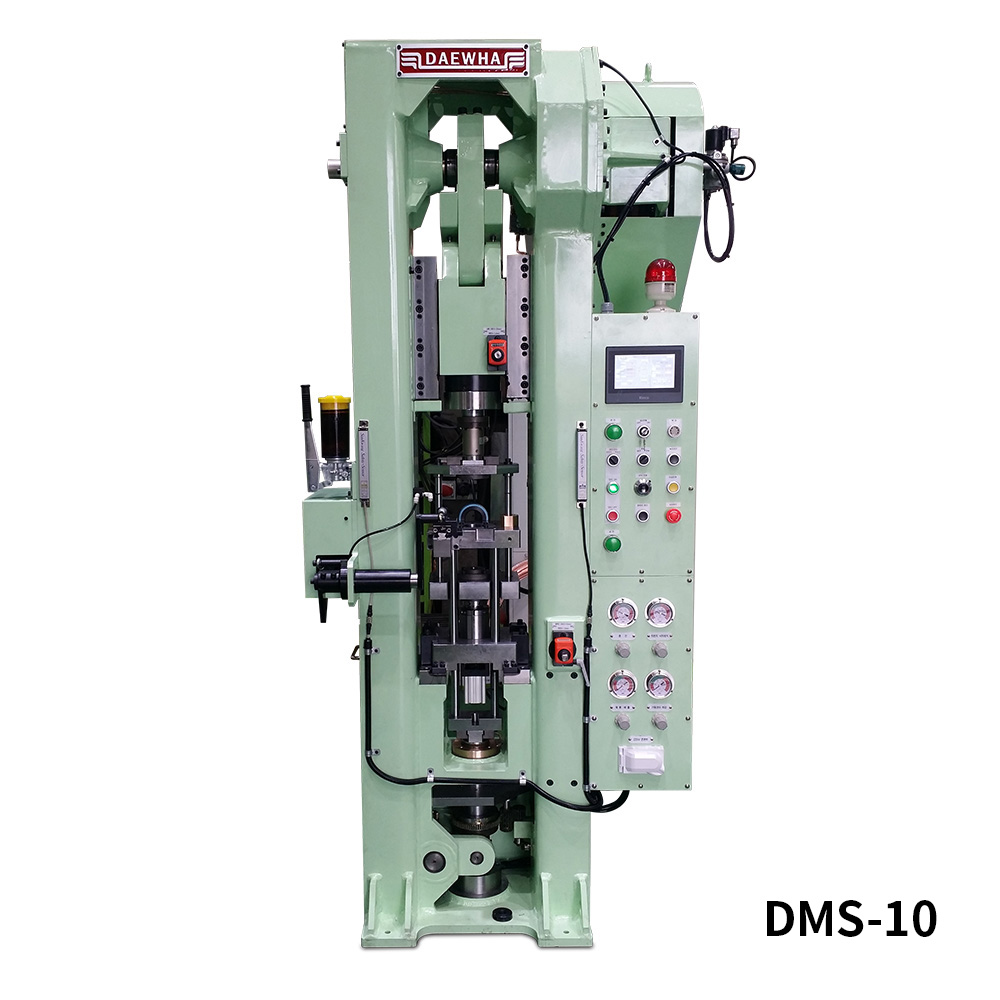

10/ 20/ 30 TON SIZING PRESS

DMS-10/ 20/ 30_Crank Type

10/ 20/ 30 TON SIZING PRESS

DMS-10/ 20/ 30_Crank Type

- It is a precise sizing press that enhances the hardness of the sintered parts by calibrating the inner and outer diameters and heights and by increasing the density.

- It is a mold setting type press using die sets that can be replaced both from the front and rear for its best convenience.

- The automation equipment and the product feeder can be easily installed on the front of the machine.

- With the ejection lever movement by ejection cam, it performs excellent extrusion.

- The space is wide enough for a multi-layer product calibration.

- The main part is located inside of a frame, so it has a good lubricating condition and minimized noise.

- A touch screen is applied even for small frames, and that makes it easy to manage the sizing data.

SPECIFICATION

Technical Data

| DESCRIPTION | UNIT | DMS-10 | DMS-20 | DMS-30 |

| 1. Max. Pressing Capacity | ton | 10 | 20 | 30 |

| 2. Max. Ejecting Capacity | ton | 5 | 12 | 20 |

| 3. Max. Diameter of Sizing | mm | 30 | 30 | 40 |

| 4. Max. Height of Sizing | mm | 25 | 40 | 50 |

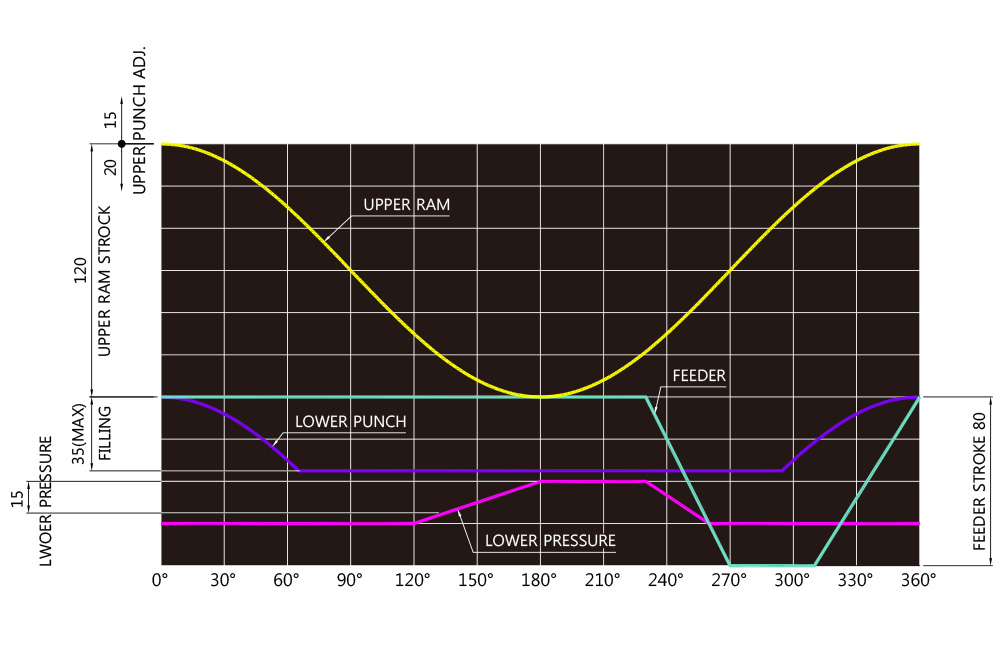

| 5. Upper Ram Stroke | mm | 80 | 100 | 100 |

| 6. Ejection Stroke | mm | 25 | 40 | 50 |

| 7. Die Resistance Capacity | ton | 5 | 10 | 15 |

| 8. Core Rod Resistance Capacity | ton | 3 | 5 | 10 |

| 9. Sizing Speed | SPM | 27~80 | 16~48 | 16~48 |

| 10. Work Supply | type | Liner | Liner | Liner |

| 11. Lubrication System | type | Grease | Oil | Oil |

| 12. Motor | KW | 2.2 | 3.7 | 5.5 |

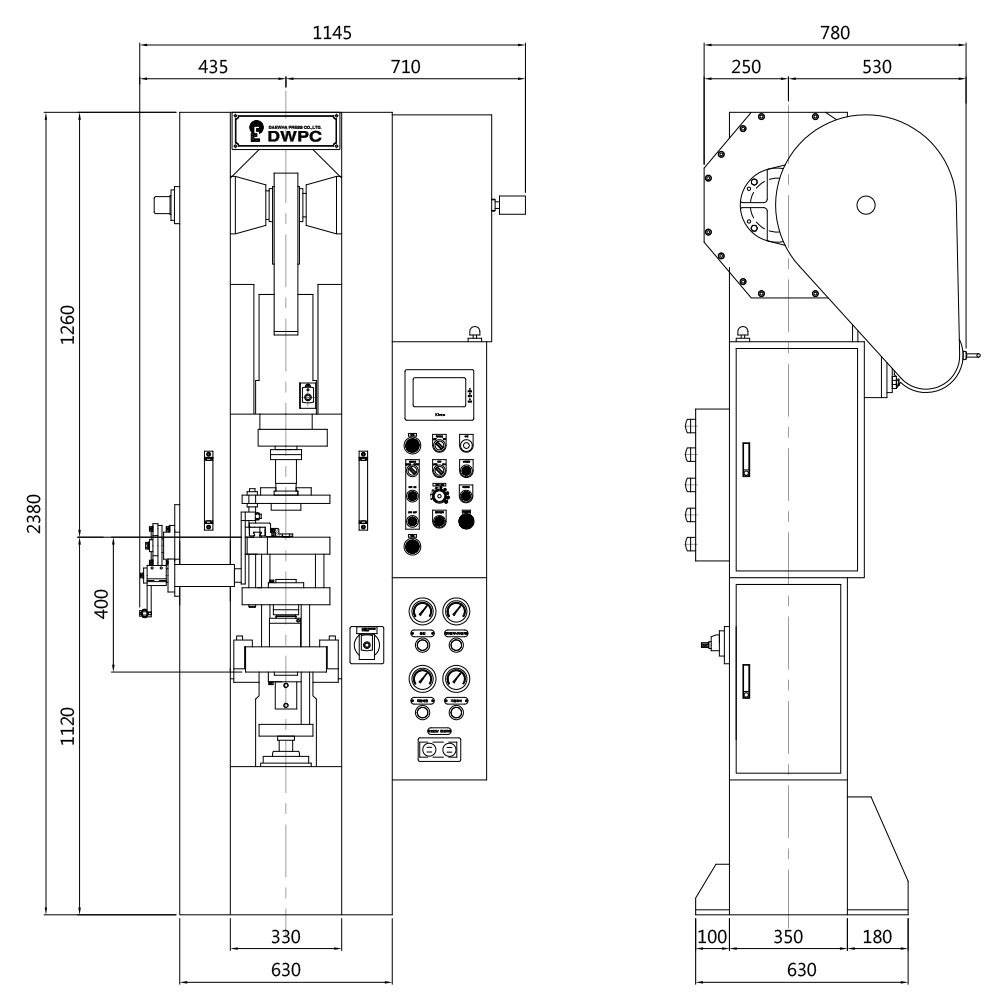

| 13. Overall Height (approx.) | mm | 2,380 | 2,600 | 2,750 |

| 14. Overall width (approx.) | mm | 1,145 | 1,150 | 1,150 |

| 15. Overall Depth (approx.) | mm | 780 | 1,300 | 1,350 |

| 16. Press Weight (approx.) | ton | 1.8 | 3.2 | 3.5 |