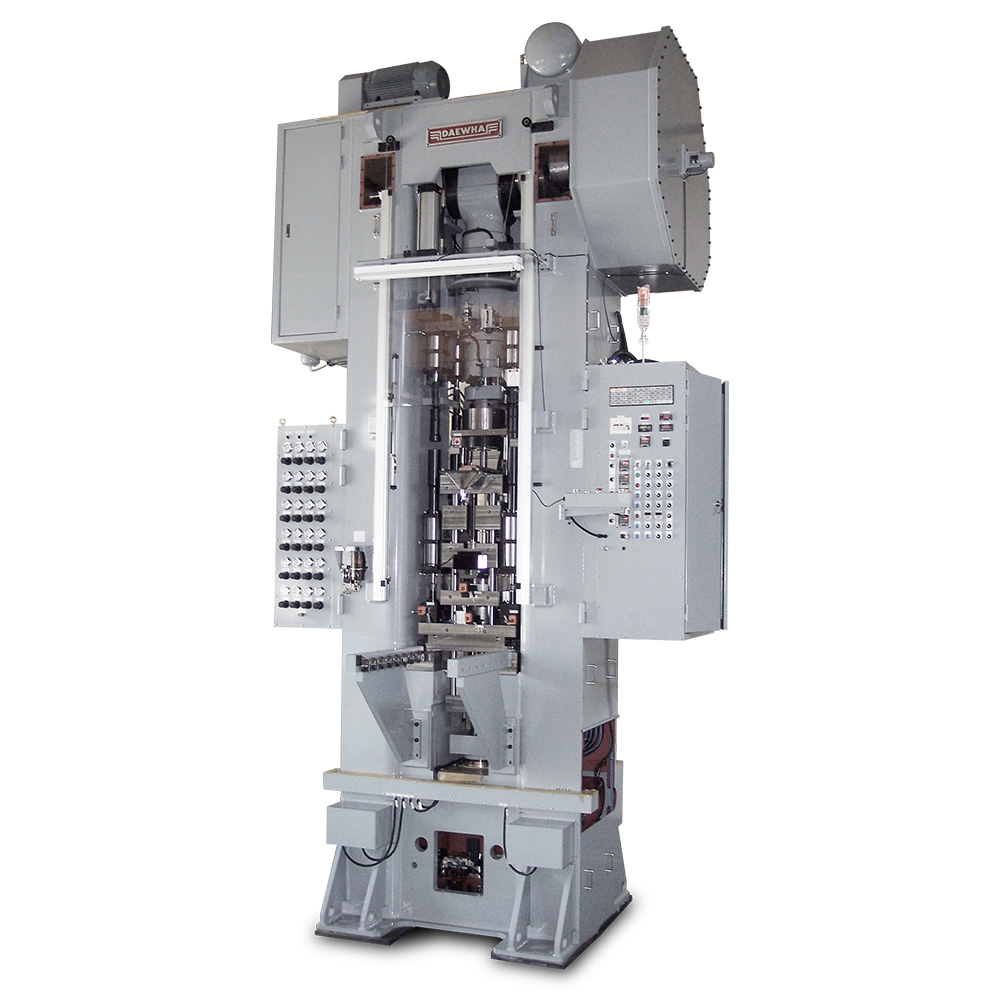

250 TON COMPACTING PRESS

DMC-250_Crank Type

250 TON COMPACTING PRESS

DMC-250_Crank Type

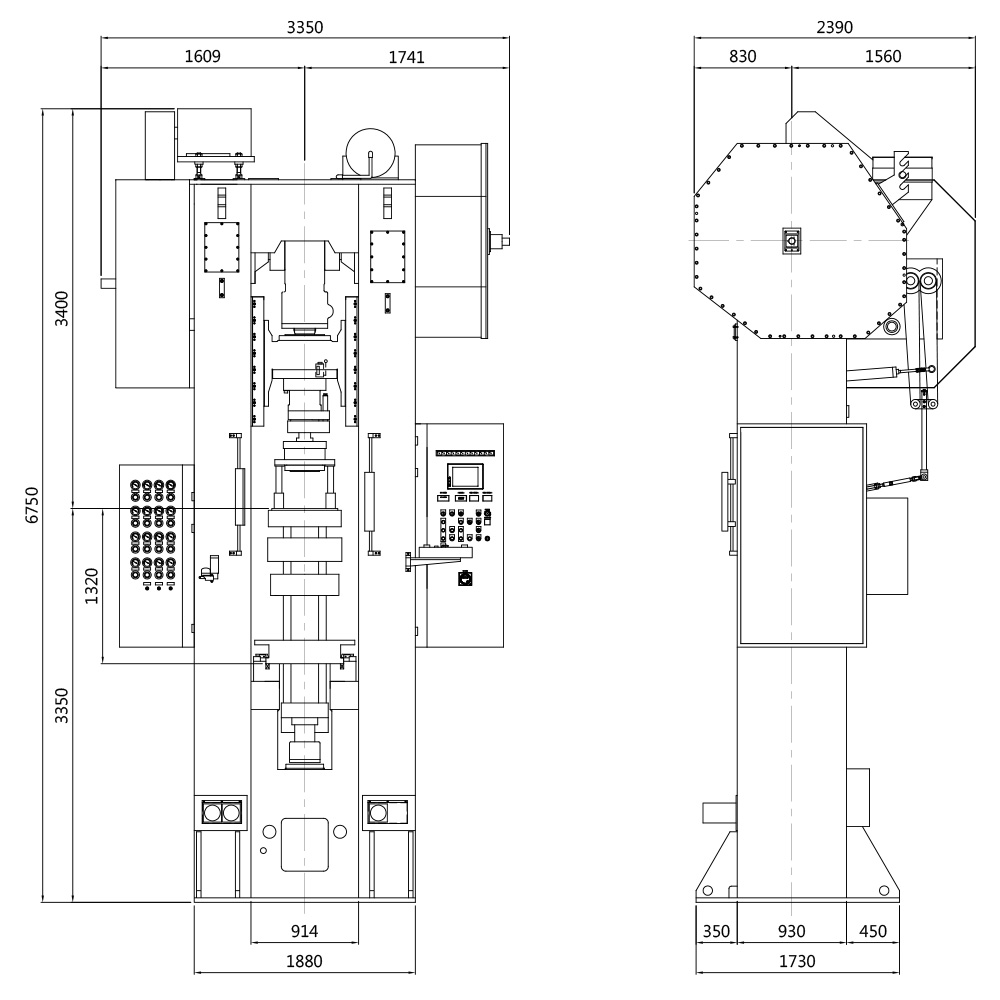

- The actuator placed on the upper part makes it easy to inspect the lower part and install additional equipment.

- It has a wide workspace, and die sets can be installed from both the front and rear. So, it is easy to install the automation and transfer system.

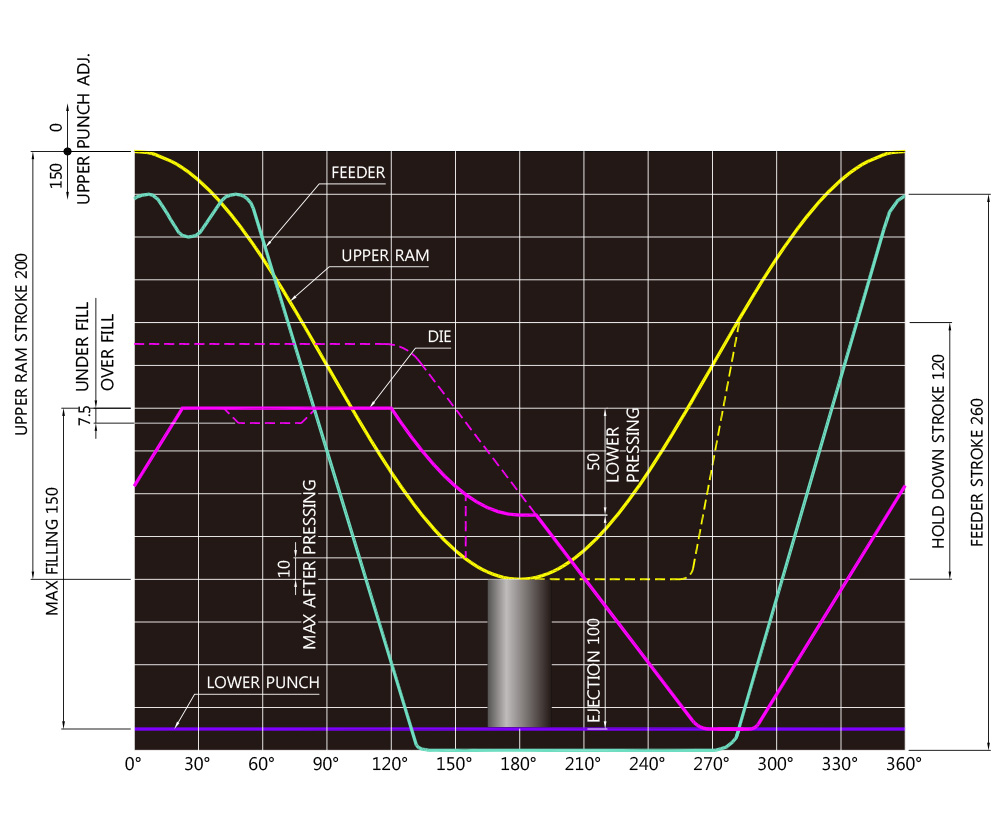

- The product is always ejected on the same place regardless of its depth. It eliminates the adjustment for each product and provides convenience for designing.

- A long stroke hold-down device is built into the upper ram, and upper punch rises up to press until the ejection to prevent cracks by springback for bigger products.

- The control device can be easily set with a touch screen. The operator can also easily set and check the amount with a digital counter showing the setpoint.

SPECIFICATION

Technical Data

| DESCRIPTION | UNIT | DMC-250 |

| 1. Max. Pressing Capacity | ton | 500 |

| 2. Max. Ejecting Capacity | ton | 180 |

| 3. Max. Filling Depth | mm | 150 |

| 4. Max. Ejecting Stroke | mm | 100 |

| 5. Upper Ram Stroke | mm | 200 |

| 6. Die Control Stroke | mm | 50 |

| 7. Upper Punch Adjustment | mm | 150 |

| 8. Die Face Adjustment Stroke | mm | ±10 |

| 9. After Pressing Stroke | mm | 10 |

| 10. Die Stopper Capacity | ton | 120 |

| 11. Max. Diameter of Compact | mm | Ø100 |

| 12. Compacting Speed | SPM | 6 – 24 |

| 13. Upper Punch Hold down | 120 | |

| 14. Under & Over Fill (Air) | 7.5 | |

| 15. Upper Punch, Filling, Stopper After Pressing, Die Face Adjustment | Motor Control | |

| 16. Compression Indicator | Digital Pressure Gauge | |

| 17. Motor | KW | 45 |

| 18. Speed Changer Type | Inverter | |

| 19. Clutch & Brake | Spring Return Type / Air Clutch | |

| 20. Lubrication System | Centralized Oil Lubrication | |

| 21. Working Air Pressure | kg/cm2 | 5-7 |

| 22. Weight (approx.) | ton | 32 |

| 23. Rotary Cam Switch | Electric Type | |

| 24. Reducer Type | Helical Gear | |

| 25. Dimension (approx.) | mm | H6,750 × W3,350 × D2,390 |