3 TON COMPACTING PRESS

DMC-3_Cam Type

3 TON COMPACTING PRESS

DMC-3_Cam Type

- The die sets are convenient in mold changes and have excellent performance.

- The internal drive runs within the lubricant tank, and it leads to high durability.

- The operation can be observed with an indicator, which is directly connected to a handle shaft, allowing easy control of each section and accurate setting.

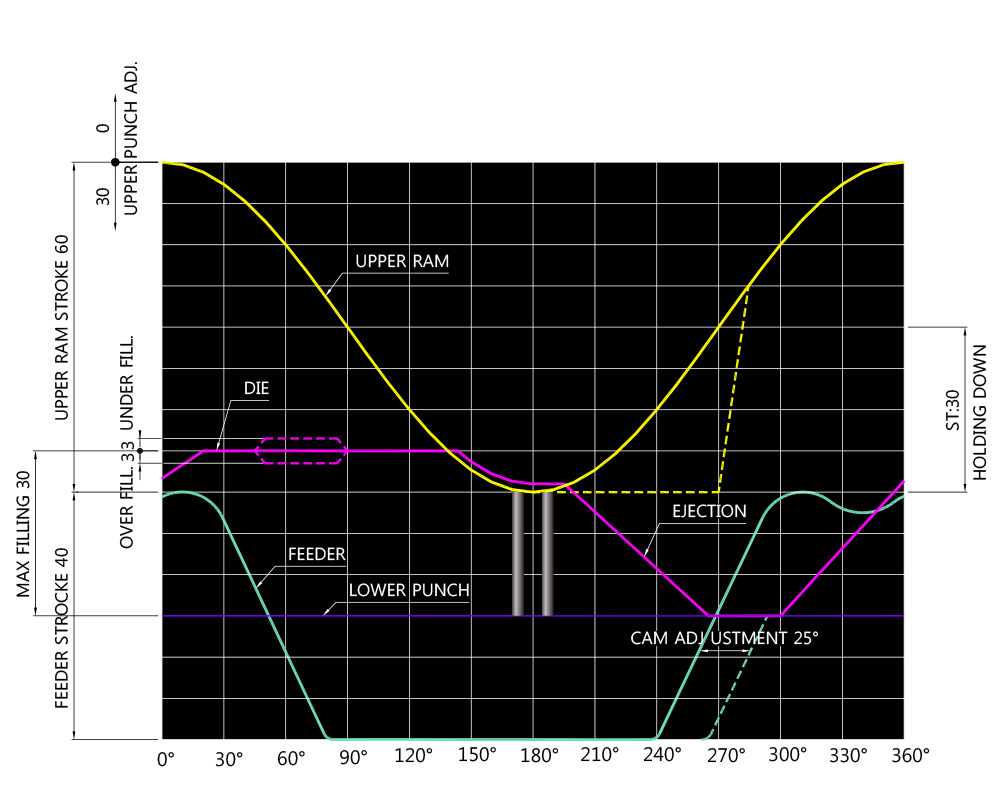

- It is easy to control the upper and lower density for the products with its non-simultaneous dual pressure die floating method.

- The enclosed structure of the actuator prevents foreign substances from entering.

- Its low noise, sudden braking system, and simple transmission enhance the safety and convenience of the operators

SPECIFICATION

Technical Data

| DESCRIPTION | UNIT | DMC-3 |

| 1. Max. Pressing Capacity | ton | 3 |

| 2. Max. Ejecting Capacity | ton | 2 |

| 3. Max. Filling Depth | mm | 30 |

| 4. Max. Ejecting Stroke | mm | 30 |

| 5. Upper Ram Stroke | mm | 50 |

| 6. Die Control Stroke | mm | 30 |

| 7. Upper Punch Adjustment | mm | 30 |

| 8. Die Face Adjustment Stroke | mm | ±5 |

| 9. Max. Diameter of Compact | mm | 30 |

| 10. Die Stopper Capacity | ton | 1.5 |

| 11. Compacting Speed (60Hz) | SPM | 20 – 80 |

| 12. Compression indicator | Oil Pressure Gauge | |

| 13. Motor | KW | 0.75 |

| 14. Speed Changer | Inverter | |

| 15. Clutch & Brake | Spring Return Type / Air Clutch | |

| 16. Lubrication | Oil Bath Type | |

| 17. Working Air Pressure | kg/cm2 | 5-7 |

| 18. Hopper Capacity (approx.) | liter | 2 |

| 19. Reducer Type | Helical Gear | |

| 20. Net Weight (approx.) | kg | 850 |

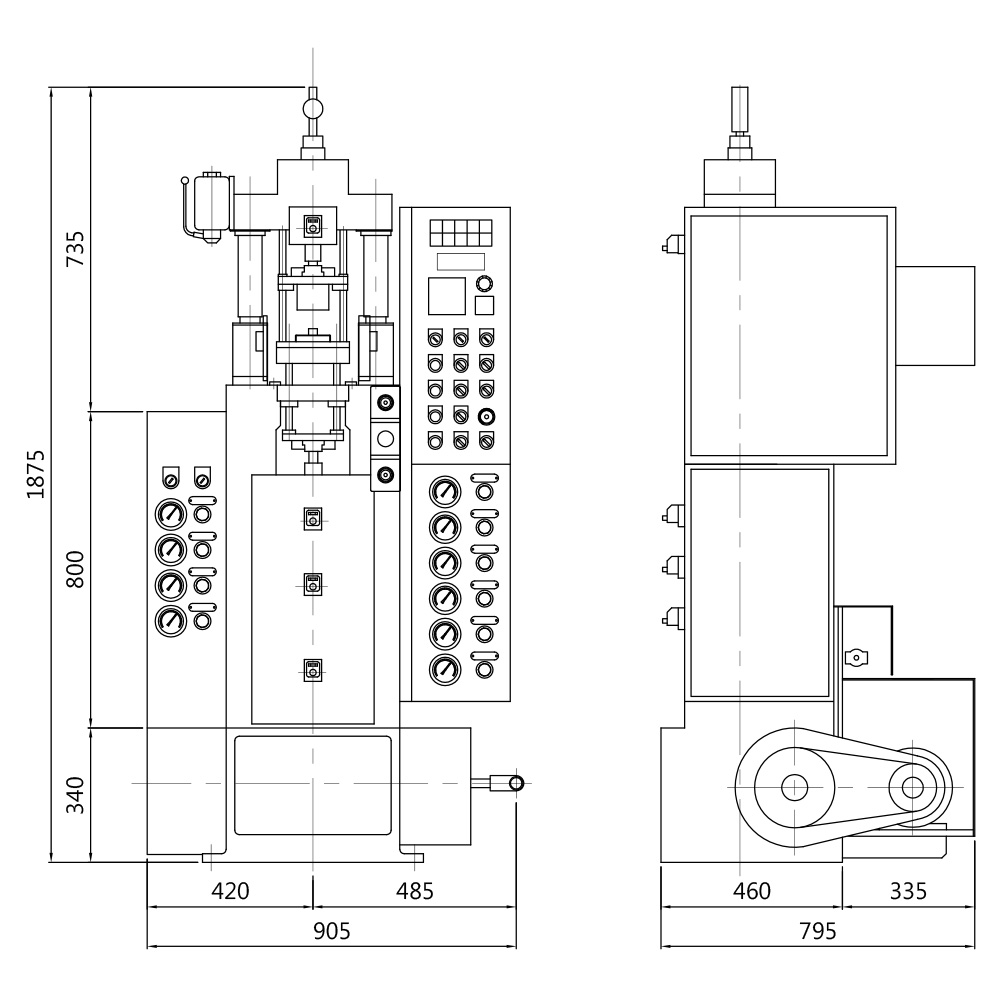

| 21. Dimension (approx.) | mm | H1,875 X W905 X D795 |