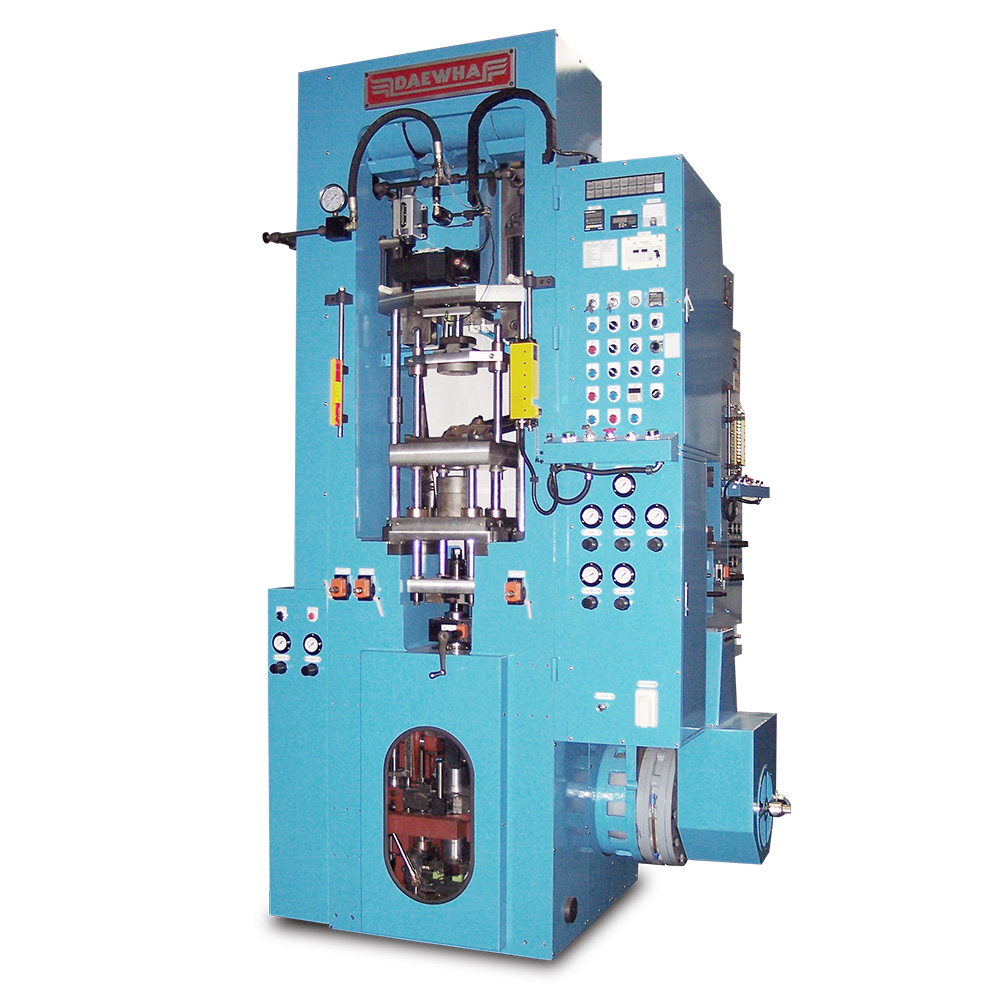

60 TON COMPACTING PRESS

DMC-60_Knuckle Type

60 TON COMPACTING PRESS

DMC-60_Knuckle Type

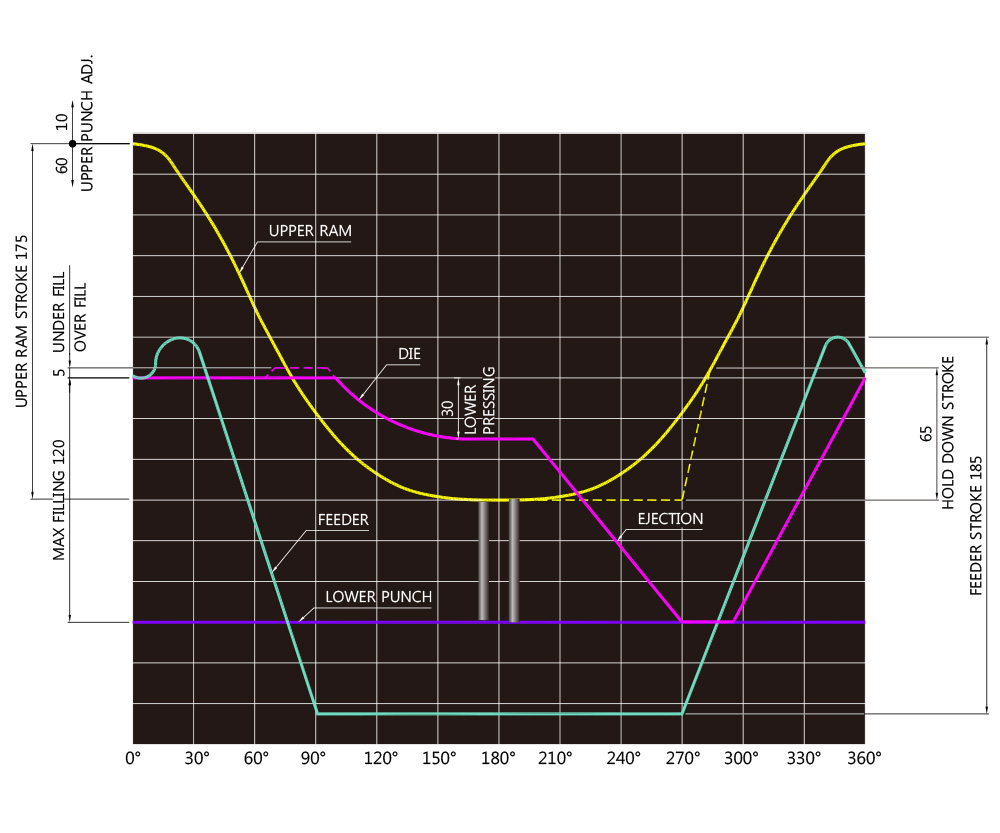

- The upper ram in knuckle type makes the compacting easier and provides excellent moldability.

- The consistent filling amount and adequate filling power can be adjusted with the lower ram filling power that runs by an air cylinder.

- It performs excellent moldability based on hydraulic and pneumatic density balance control.

- The stopper position can be adjusted, and it is easy to set the pressure for both simultaneous and non-simultaneous.

- The product is always ejected on the same place regardless of its depth. It eliminates the adjustment per product and provides convenience for designing.

- The operation can be observed with an indicator, which is directly connected to a handle shaft, allowing easy control of each section and accurate setting.

SPECIFICATION

Technical Data

| DESCRIPTION | UNIT | DMC-60 |

| 1. Max. Pressing Capacity | ton | 60 |

| 2. Max. Ejecting Capacity | ton | 40 |

| 3. Max. Filling Depth | mm | 120 |

| 4. Max. Ejecting Stroke | mm | 120 |

| 5. Upper Ram Stroke | mm | 175 |

| 6. Die Control Stroke | mm | 120 |

| 7. Upper Punch Adjustment | mm | 70 |

| 8. Die Face Adjustment Stroke | mm | ±10 |

| 9. Max. Diameter of Compact | mm | 100 |

| 10. Die Stopper Capacity | ton | 30 |

| 11. Compacting Speed (60Hz) | SPM | 8 – 24 |

| 12. Compression indicator | Oil Pressure Gauge | |

| 13. Motor | KW | 11 |

| 14. Speed Changer | Inverter | |

| 15. Clutch & Brake | Spring Return Type / Air Clutch | |

| 16. Lubrication | Centralized Oil Lubrication | |

| 17. Working Air Pressure | kg/cm2 | 5-7 |

| 18. Hopper Capacity (approx.) | liter | 60 |

| 19. Reducer Type | Cyclo Reducer | |

| 20. Net Weight (approx.) | kg | 7,000 |

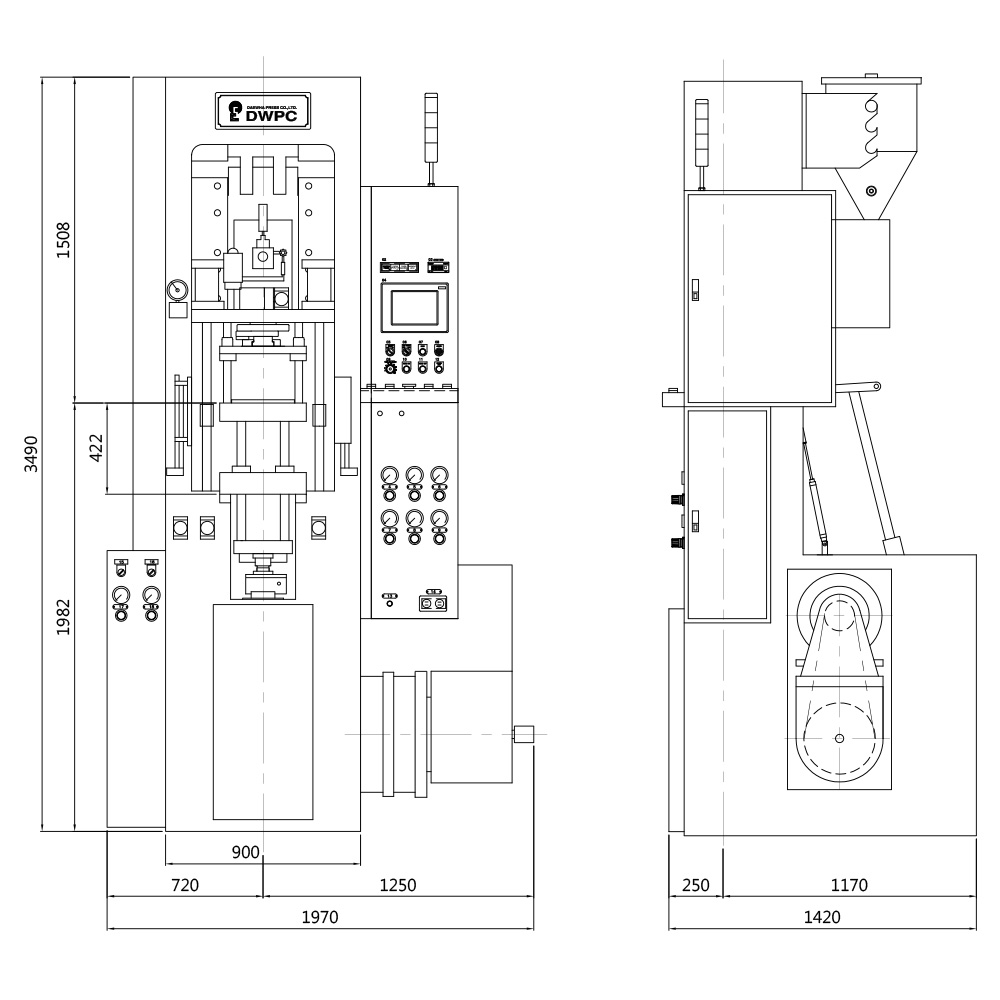

| 21. Dimension (approx.) | mm | H3,490 × W1,970 × D1,420 |